Testing the Durability and Quality of SIP Panels

Test 1: Strength and Tool Challenge

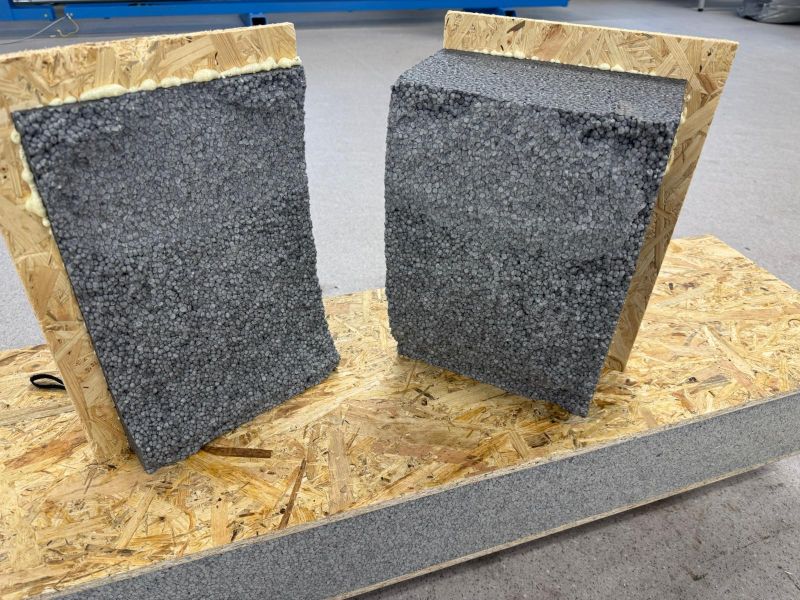

In the first experiment, a SIP panel piece measuring approximately 1 meter by 1 meter was used. The goal of the test was to assess the adhesive bond strength between the OSB boards and the NEOPOR core. Initially, attempts to separate the panel layers using only manual force demonstrated that the bond could withstand significant mechanical stress.

A heavy tool—a pipe wrench—was then used to separate the layers. After more than 20 strong impacts on the edge of the OSB board, the panel piece was broken. However, the results showed that the adhesive joint remained intact, while the fracture appeared within the NEOPOR material itself.

This result confirms the high manufacturing quality and durability of NEOPOR EPS-80. Even in a small format, the material withstood significant mechanical stress that traditional insulation materials, such as mineral wool, cannot endure.

Conclusion: The experiment demonstrated the high quality of the adhesive bond and the panel's overall durability.

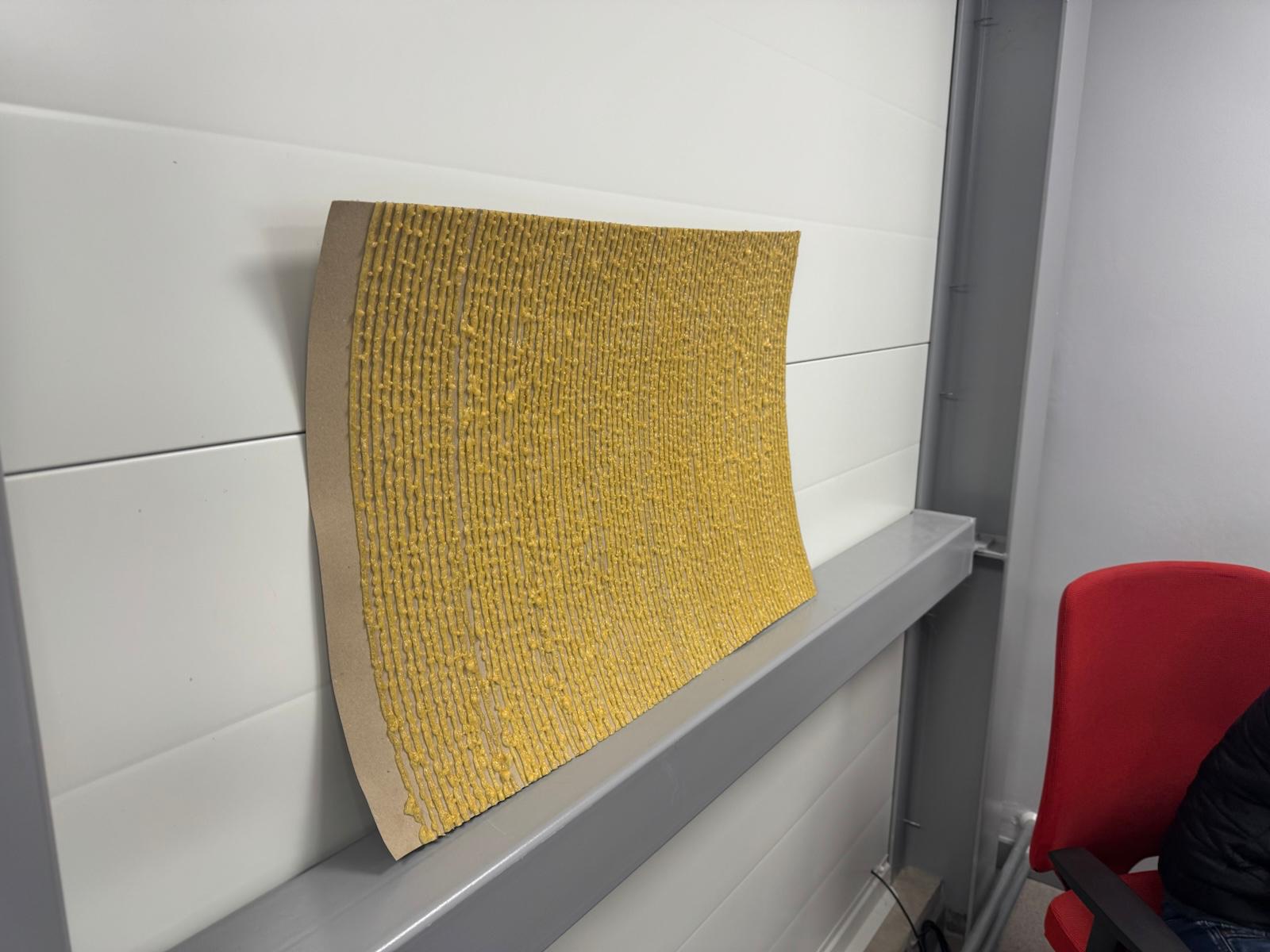

Example of adhesive application density:

Test 2: Long Panel Strength Test

In the second experiment, a longer piece of NEOPOR EPS-80, measuring 3 meters in length and 26 cm in width, was tested. The aim was to determine whether the board could be broken by applying pressure to its central part.

During the test, the board was placed on two wooden supports so that its middle section was unsupported. Initially, a 90 kg load, equivalent to a person's body weight, did not break the board. To further test its strength, two additional people were added, bringing the total load to 270 kg. Despite the significant pressure, the SIP panel remained intact and did not produce cracking sounds.

Conclusion: The test results showed that larger SIP panels provide even greater durability and can withstand significant loads.

Why SIP Panels Are Superior

The high strength of SIP panels lies in their monolithic structure. Unlike traditional timber frame constructions filled with insulation materials, SIP panels are an integrated system where OSB and NEOPOR form a cohesive unit. This structure ensures even load distribution and eliminates weak points typical of other materials.

For projects requiring long-lasting, energy-efficient, and durable solutions, SIP panels are an ideal choice. The conducted tests further confirmed the reliability and quality of these panels, making them an indispensable solution for various construction needs.