Netatmo Weather Station

Measurable precision: how the Netatmo weather station helps us produce top-quality SIP panels

In our factory, everything starts with the environment. Literally.

When manufacturing Structural Insulated Panels (SIP), not only the material composition matters but also the conditions under which panels are made. Temperature, humidity, and air quality all influence the mechanical properties, adhesive quality, and long-term durability of the panels.

That’s exactly where Netatmo smart weather stations come in.

Why Is SIP Panel Manufacturing Only Carried Out in a Controlled Climate?

SIP panels are a high-precision building material where quality is of critical importance. One of the key factors influencing the durability and service life of the final product is the production environment—specifically the temperature and humidity during panel bonding.

In our facility, the SIP panel bonding process takes place in a climate-controlled room, where optimal temperature and relative humidity are maintained year-round, regardless of external weather conditions. This is crucial because the adhesive reaction is highly sensitive to environmental factors; inappropriate temperature or humidity can weaken bond strength and, over time, compromise the panel’s structural integrity.

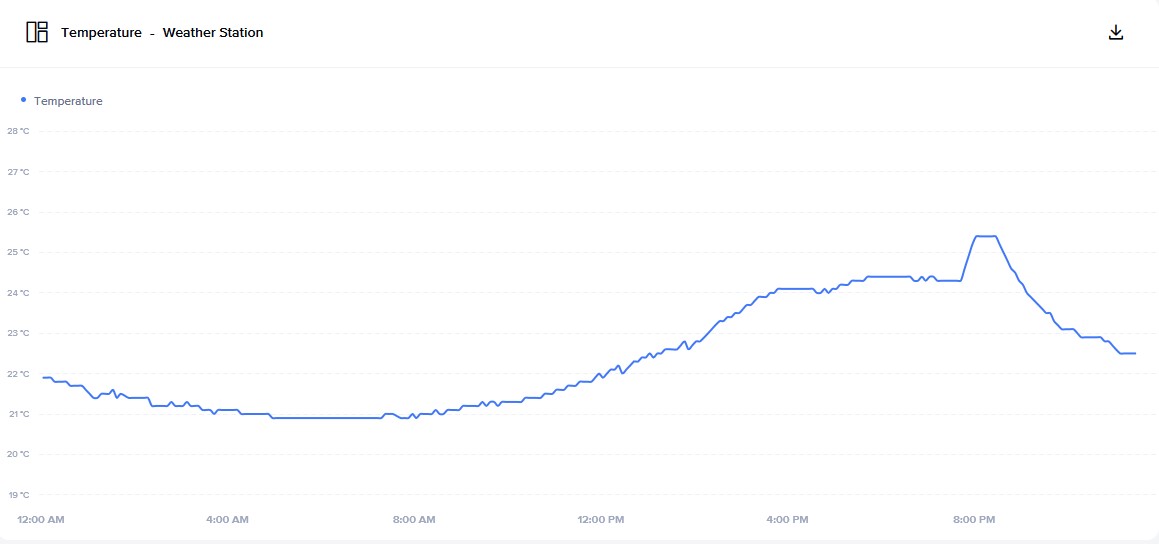

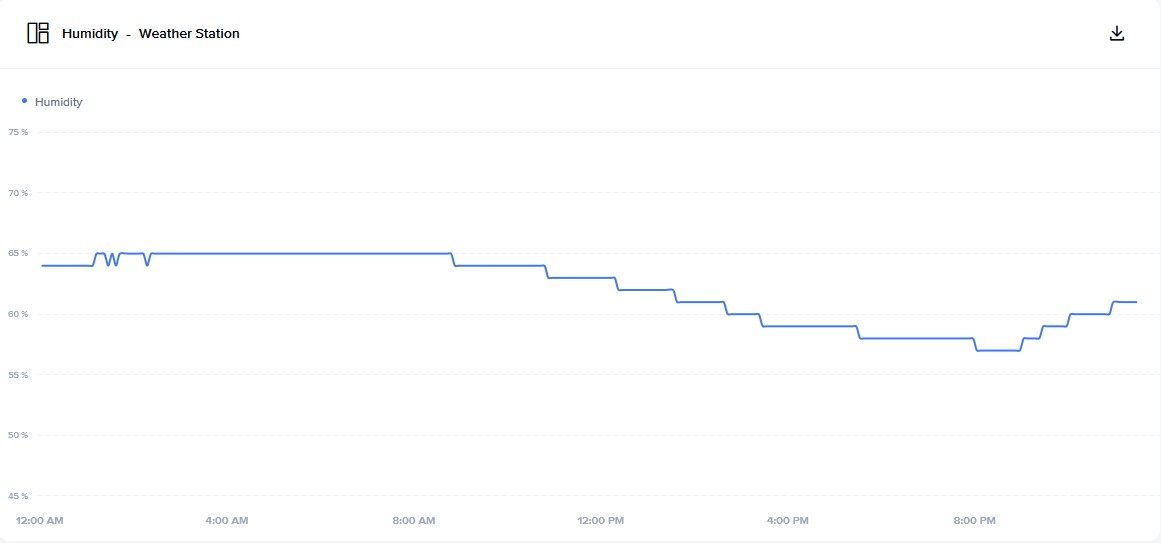

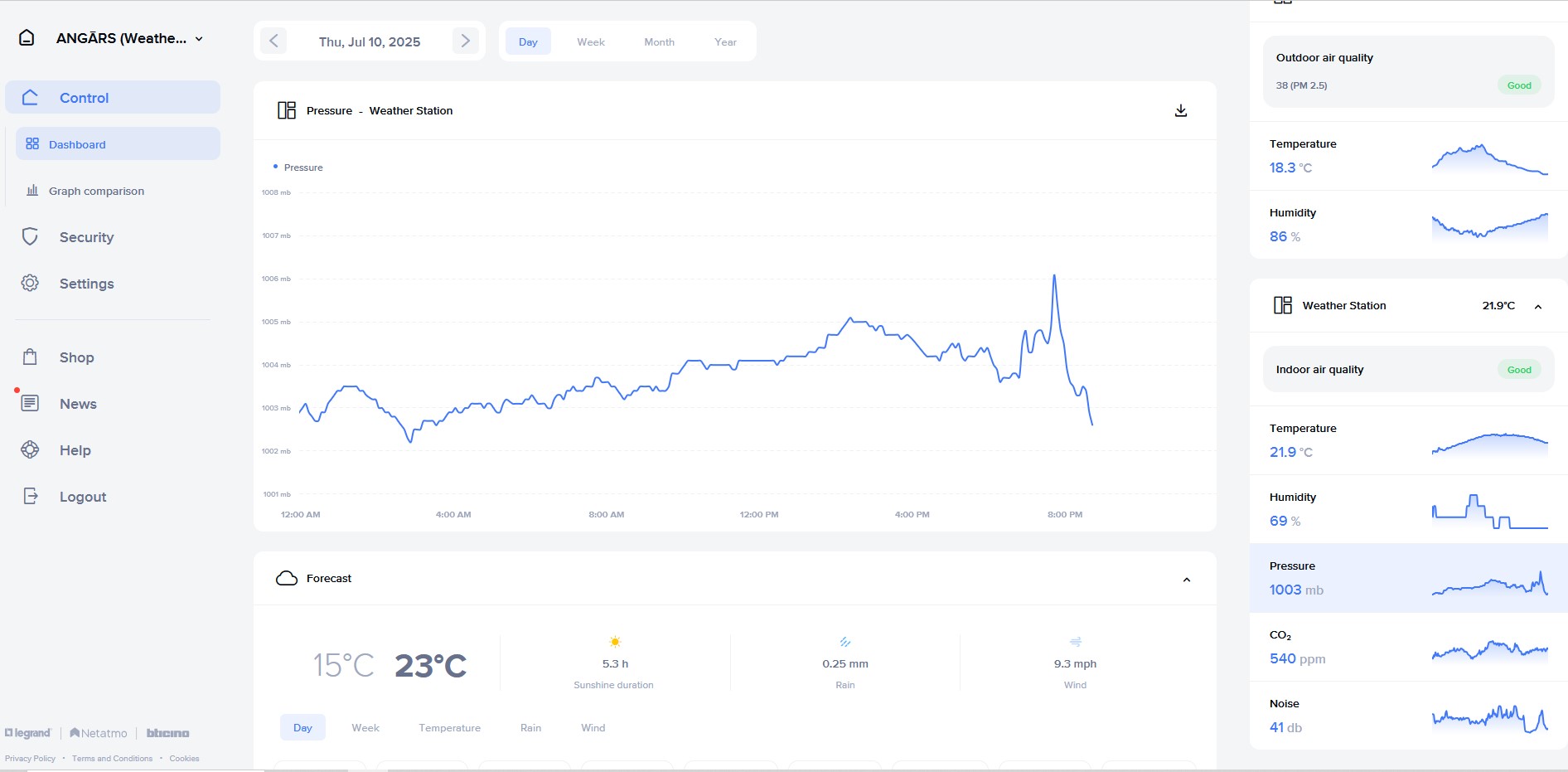

To ensure consistently high quality, we use a Netatmo weather station to continuously monitor room parameters: temperature, humidity, and air quality. All data are automatically logged, enabling us to review the exact climate conditions at any given point in production.

-

Temperature – ensuring optimal conditions for bonding and curing.

-

Humidity – too dry air can cause cracks or weak adhesion; too humid can affect material strength.

-

Outdoor climate – crucial for seasonal adjustments and drying regimes.

Why it matters?

Better adhesive performance — thanks to temperature-controlled gluing conditions.

Fewer defects — because we monitor the environment continuously, not just once a day.

-

Customer transparency — we can provide conditions for any specific panel.

-

Smarter production — Netatmo data helps us adapt the process to seasons or weather.

We go beyond the minimum!

Most SIP panel manufacturers focus on materials, but we go a step further by monitoring the environment in which these materials are processed. We believe that quality begins with process discipline and environmental control; therefore, each step of SIP panel production is carried out with care and transparency.

Want to learn more? Contact us to find out how smart climate control helps us create SIP panels that last longer, insulate better, and perform safer.

Want to learn more? Contact us to find out how smart climate control helps us create SIP panels that last longer, insulate better, and perform safer.